Worldwide Sourcing and Manufacturing of Precision Mechanical Fixtures

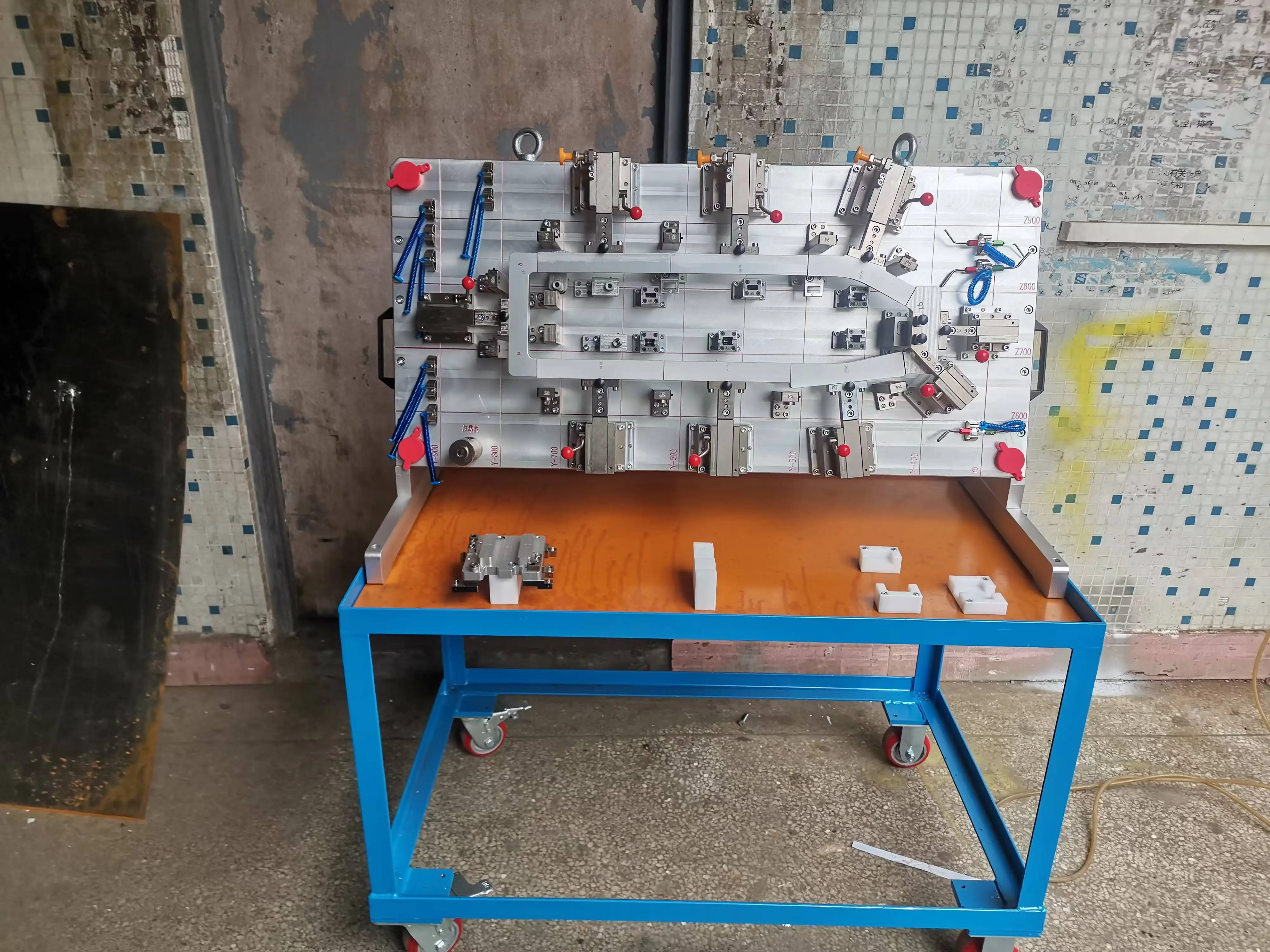

Precision mechanical pieces play an important role in modern industries like vehicle, aerospace, and consumer electronics, and jigs and fixtures are in the core regarding ensuring effective production processes. With improvements in global sourcing, enterprises now have usage of world-class manufacturers that specialize in jigs manufacturing and even fixtures manufacturing. This post provides important insights for businesses planning to source these components globally. Just how to Choose a trusted Export-Ready Jigs Maker Finding a trusted partner for jigs and fixtures developing begins with examining the manufacturer's qualifications. Export-ready companies commonly comply with international criteria like ISO accreditations that guarantee product or service quality and uniformity. Their expertise in creating customized clamps, jigs, and features tailored to automotive or even aerospace industry requirements is paramount. Organizations must inquire about their design discussion processes, particularly to be able to gauge the finely-detailed of their executive solutions. Additionally, producers that provide end-to-end support, from prototyping to mass generation, minimize logistical obstacles. By way of example, some China manufacturers excel inside providing customized alternatives for diverse sectors while working using materials like steel, aluminum, and high-performance plastics in order to meet your unique project needs. What International Purchasers Should Know Concerning Chinese Fixture Vendors  Customer a worldwide leader in lures manufacturing and fixtures production, with suppliers who constantly pioneer to meet different global demands. Even so, human hair wigs must carry out homework when finding from Chinese suppliers. Evaluating customer customer feedback, company portfolios, and detailed case studies is critical for comprehending their capabilities. For example, companies such as Shenzhen Yongxinglong are skilled in high-quality lures and fixtures for industries such since automotive and consumer electronics. Additionally, their dedication to using advanced automation technology, this kind of as welding robots and automation tools, enhances the accurate and efficiency of the fixtures. Buyers also need to confirm whether the particular supplier ships around the globe and provides a soft communication process. Ensuring that suppliers offer transparency on guide times, material selections, and customization steps is key to fostering long-term close ties. Quality Control Protocols for Exported Precision Mechanical Parts Sustaining stringent quality handle is crucial in making certain precision physical parts meet useful and safety criteria. Reliable manufacturers include all-encompassing protocols at every stage involving production, from material sourcing to last inspection. For example, aesthetic inspection technologies want laser structural optic measurement or photograph documentation ensure typically the accuracy connected with sophisticated fixtures and jigs manufacturing. Additionally, companies carry out tension tests, durability assessments, and measurements to fit the intricate specs of precision mechanical parts. Companies putting first process certifications like ISO 9001 demonstrate their commitment to be able to excellence. Another outstanding practice involves group sampling to guarantee consistency across large-scale production. Communication between the buyer in addition to the manufacturer throughout pre-production consultations ensures your requirements are usually meticulously addressed in the course of these quality handle stages. Logistics in addition to Lead Time Considerations for Global Fitting Orders Logistics will be another critical component when sourcing jigs and fixtures throughout the world. Factors such because lead times, shipping and delivery methods, and warehouse capabilities should always be evaluated before putting bulk orders. Export-ready suppliers should offer realistic timelines based on the intricacy and volume associated with the order. Regarding companies shipping globally, manufacturers like Shenzhen Yongxinglong provide not only efficient delivery timelines but also bulk order options for your business requiring considerable production. Using Daviswigs manufacturing methods such as CNC machining in addition to robotic technologies enhances production speed and even helps achieve more quickly lead times without having compromising on high quality. Clear communication channels and tracking revisions also streamline order fulfillment, ensuring organizations can incorporate lures and fixtures straight into their workflows promptly. Understanding tariff constructions, ensuring compliance using international trade rules, and negotiating conditions also contribute to be able to smoother logistics runs. To summarize, the effective integration of sophisticated manufacturing methods, streamlined communication, and solid logistics planning is essential for enhancing the production plus delivery of lures and fixtures. Simply by emphasizing quality, acceleration, and compliance, companies can enhance their operational efficiency and even remain competitive in the global marketplace. With the appropriate strategies in spot, companies can easily meet industry requirements and achieve extensive success.

Customer a worldwide leader in lures manufacturing and fixtures production, with suppliers who constantly pioneer to meet different global demands. Even so, human hair wigs must carry out homework when finding from Chinese suppliers. Evaluating customer customer feedback, company portfolios, and detailed case studies is critical for comprehending their capabilities. For example, companies such as Shenzhen Yongxinglong are skilled in high-quality lures and fixtures for industries such since automotive and consumer electronics. Additionally, their dedication to using advanced automation technology, this kind of as welding robots and automation tools, enhances the accurate and efficiency of the fixtures. Buyers also need to confirm whether the particular supplier ships around the globe and provides a soft communication process. Ensuring that suppliers offer transparency on guide times, material selections, and customization steps is key to fostering long-term close ties. Quality Control Protocols for Exported Precision Mechanical Parts Sustaining stringent quality handle is crucial in making certain precision physical parts meet useful and safety criteria. Reliable manufacturers include all-encompassing protocols at every stage involving production, from material sourcing to last inspection. For example, aesthetic inspection technologies want laser structural optic measurement or photograph documentation ensure typically the accuracy connected with sophisticated fixtures and jigs manufacturing. Additionally, companies carry out tension tests, durability assessments, and measurements to fit the intricate specs of precision mechanical parts. Companies putting first process certifications like ISO 9001 demonstrate their commitment to be able to excellence. Another outstanding practice involves group sampling to guarantee consistency across large-scale production. Communication between the buyer in addition to the manufacturer throughout pre-production consultations ensures your requirements are usually meticulously addressed in the course of these quality handle stages. Logistics in addition to Lead Time Considerations for Global Fitting Orders Logistics will be another critical component when sourcing jigs and fixtures throughout the world. Factors such because lead times, shipping and delivery methods, and warehouse capabilities should always be evaluated before putting bulk orders. Export-ready suppliers should offer realistic timelines based on the intricacy and volume associated with the order. Regarding companies shipping globally, manufacturers like Shenzhen Yongxinglong provide not only efficient delivery timelines but also bulk order options for your business requiring considerable production. Using Daviswigs manufacturing methods such as CNC machining in addition to robotic technologies enhances production speed and even helps achieve more quickly lead times without having compromising on high quality. Clear communication channels and tracking revisions also streamline order fulfillment, ensuring organizations can incorporate lures and fixtures straight into their workflows promptly. Understanding tariff constructions, ensuring compliance using international trade rules, and negotiating conditions also contribute to be able to smoother logistics runs. To summarize, the effective integration of sophisticated manufacturing methods, streamlined communication, and solid logistics planning is essential for enhancing the production plus delivery of lures and fixtures. Simply by emphasizing quality, acceleration, and compliance, companies can enhance their operational efficiency and even remain competitive in the global marketplace. With the appropriate strategies in spot, companies can easily meet industry requirements and achieve extensive success.